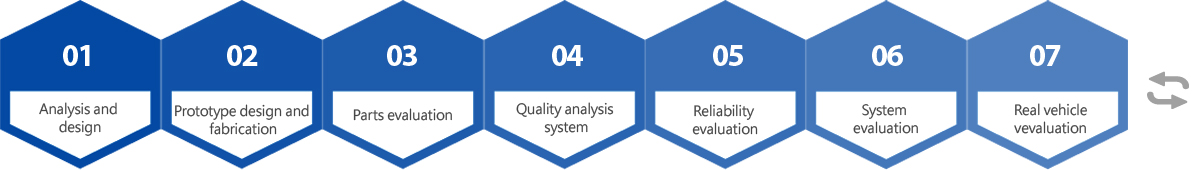

Connected R&D System

From design to real vehicle test – one stop system

- Analysis and design

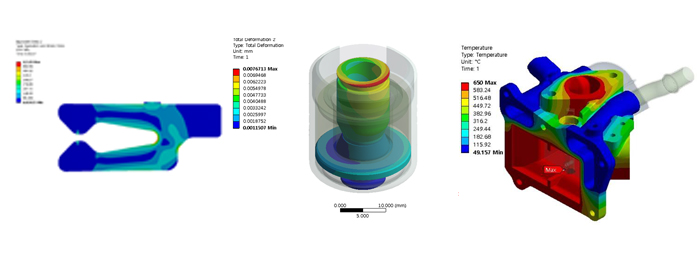

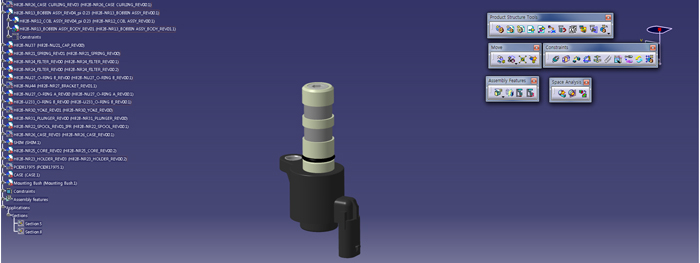

- We dramatically reduce design time and develop products meeting our customer’s diverse requirements, through customized design (Pro-e, CATIA) and advanced techniques for the analysis of strength, magnetic force, fluid, tolerance, and flow.

- Prototype design and fabrication

- The proto shop is operated, which makes it possible to fabricate a prototype through the self-processing and assembly of design as it is on the basis of analysis.

- Parts evaluation

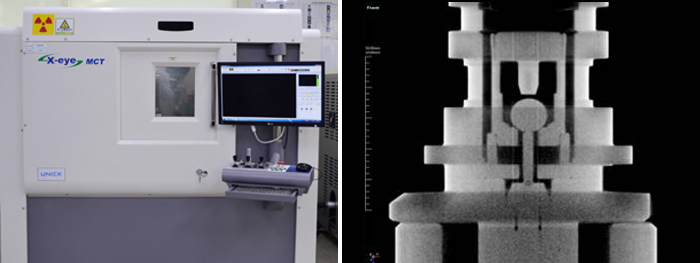

- We have equipment capable of the evaluation, testing and improvement of all performances required by customers as well as our own performance evaluation of parts.

- Quality analysis system

- We can improve the quality of parts during product development or before mass production, using our own core analysis equipment.

- Reliability evaluation

- We can conduct on our own the evaluation and testing of reliability test items required by customers, and can develop reliable parts through standardization operation based on our own standard for durability.

- System evaluation

- We can conduct system evaluation on a module basis (automatic transmission lever, oil pump, etc.) as well as the evaluation of individual parts. And we can support the development of customized parts for our customer’s system, thereby enhancing the reliability of part development.

- Real vehicle evaluation

- We mount parts on a real vehicle, evaluate their impacts, and create a database, thereby carrying out part development that provides customer confidence.